- -11%

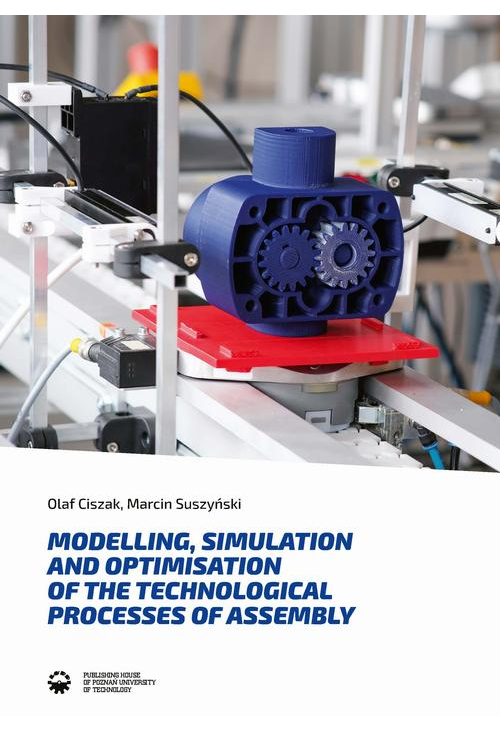

ebook Modelling, simulation and optimisation of the technological processes of assembly

W dzisiejszym konkurencyjnym świecie coraz większe znaczenie mają procesy technologiczne związane z montażem ręcznym i zautomatyzowanym. Warto więc badać skuteczne metody i modele ich implementacji. Rozwiązywanie problemów dotyczących najbardziej kosztownych i pracochłonnych elementów procesu produkcyjnego, jakim jest montaż, powinno podlegać ciągłemu rozwojowi i optymalizacji. Z drugiej strony właśnie w tej części procesu znajdują się największe rezerwy umożliwiające poprawę i zwiększenie efektywności produkcji.

W niniejszej monografii podjęto próbę skompensowania wybranych i różnorodnych procesów montażowych, opierając się na autentycznych przykładach praktycznych, jak np. algorytmy zapisu struktur czy optymalizacja procesów planowania montażu. Przedstawione metody i systemy ilustrują główne, wybrane trendy widoczne obecnie w projektowaniu i ulepszaniu procesów montażowych. Opisane w tej monografii algorytmy i heurystyki mogą znaleźć zastosowanie, przede wszystkim w planowaniu montażu ręcznego oraz wspomaganego komputerowo.

"Modelling, simulation and optimisation of the technological processes of assembly" to ebook napisany przez Olafa Ciszaka i Marcina Suszyńskiego, wydany w 2021 roku przez Wydawnictwo Politechniki Poznańskiej. Ta publikacja cyfrowa dostępna jest w języku angielskim i stanowi cenne źródło wiedzy dla każdego zainteresowanego optymalizacją procesów montażowych.

Jeśli szukasz książek elektronicznych dotyczących innowacji w przemyśle, chcesz pobrać ebook w formacie PDF lub po prostu interesuje Cię literatura z dziedziny technologii i inżynierii, ten tytuł jest dla Ciebie. Odwiedź nasz sklep z ebookami, aby kupić "Modelling, simulation and optimisation of the technological processes of assembly" i cieszyć się wygodnym czytaniem na dowolnym urządzeniu. To jeden z najlepszych ebooków w swojej kategorii!

Spis treści ebooka Modelling, simulation and optimisation of the technological processes of assembly

Definitions and symbols 71. Introduction 10

2. Technological process of assembly 13

2.1. Role and importance of assembly in the technical preparation of production 14

2.2. Designing the technological assembly process 17

2.3. Integrated assembly model 21

2.4. Automation and robotisation of the technological process of assembly 22

2.5. Assembly sequence planning 25

2.6. Conclusions 35

3. Assembly sequence planning with a directed hypergraph, digraph, state matrix and graph 38

3.1. Introduction 38

3.2. Base Part Selection 39

3.3. From hypergraph to directed graph 42

3.4. Matrix representation of the design 44

3.5. Assessment of transitions between assembly states 46

3.6. Selection of the extreme path in a directed graph 48

3.7. Example of an algorithm for ASP 51

3.8. Determining the assembly sequence with the use of the Msassembly software 54

3.9. An example of a flexible robotic assembly system 59

3.10. Assumptions for a flexible robotic assembly system 59

3.11. Assembly unit identification system 62

3.12. Generation of assembly sequences feasible in terms of design constraints 64

3.13. Assembly sequence assessment 66

3.14. Conclusions 67

4. Example of modelling and simulation of the technological process of assembly of a machining centre 68

4.1. Introduction 68

4.2. Measurements of labour input required for individual operations 69

4.2.1. Timing stages 69

4.3. Stages of conducting a working day activity study 72

4.4. The technological process of assembly of the machining centre 74

4.5. CAD simulation 75

4.5.1. Introduction 75

4.5.2. CAD System 76

4.5.3. Modelling assemblies (products) 76

4.5.4. Presentation and documentation of assembly 79

4.6 Balancing the final assembly line of the machining centre 81

4.7 Modelling and simulation of the technological process of assembly of a machining centre 88

4.8 Development of work regulations, methods of communication and the algorithm of the functioning of the information and diagnostic system as part of the active control and supervision of operation of the assembly line 93

4.8.1. Assumptions 93

4.8.2. System structure 95

4.8.3. System operation 97

4.9 Simulation tests of the information and diagnostic system and the technological process of assembly of the machining centre, adopting the final structure 109

4.9.1. Simulation tests of the information and diagnostic system and the technological process of assembly of the machining centre 109

4.9.2. Conclusions 117

5. Modelling and simulation of the technological assembly process, taking into account MTBF 119

5.1. Mean Time Between Failures – MTBF 119

5.2. The process of assembling the dashboard to the car body 120

5.3. Modelling and simulation of the assembly cell for assembling the dashboard to the car body 121

5.4. Conclusions 124

6. Examination of the efficiency of the assembly cell for the assembly of the main spindle to the turning centre 126

6.1. Assembly technology of the main headstock 126

6.2. Examination of the labour input required for the assembly operations 127

6.3. Operation sequence 128

6.4. Modelling and simulation of the assembly cell 128

6.5. Conclusions 131

7. Summary and conclusions 135

References 137

Szczegóły ebooka Modelling, simulation and optimisation of the technological processes of assembly

- Wydawca:

- Wydawnictwo Politechniki Poznańskiej

- Rok wydania:

- 2021

- Typ publikacji:

- Ebook

- Język:

- angielski

- Format:

- Liczba stron:

- 143

- ISBN dla wersji papierowej:

- 9788377756355

Recenzje ebooka Modelling, simulation and optimisation of the technological processes of assembly

-

Reviews (0)

Na jakich urządzeniach mogę czytać ebooki?

- -11%

@CUSTOMER_NAME@

@COMMENT_TITLE@

@COMMENT_COMMENT@